Empowering countries to make their own vaccines may sound like a herculean task, but it is all in a day’s work for the Technology Transfer Initiative team at the World Health Organization.

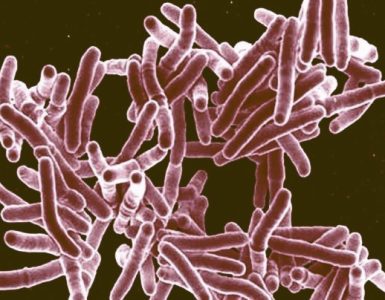

Many of us may recall our childhood trips to the doctor’s clinic to receive a routine immunization on the arm. These visits – however unpleasant – were important: experts estimate these injections help to prevent two to three million childhood deaths each year.

But while vaccines are still the least expensive way of controlling the spread of infectious diseases, with limited distribution channels and the lack of a lucrative market in the developing world, it is more the rule than the exception there for children to die of common childhood conditions such as measles.

According to Dr. Margaret Chan, Director-General of the World Health Organization (WHO), at the 2011 Pacific Health Summit, “a vaccine that is too expensive for the developing world is worse than no vaccine at all.”

Indeed, pharmaceutical companies have heeded the call to make vaccines available to those who cannot afford them. In June last year, leading drug companies announced dramatic slashes in vaccine prices for the developing world, including a 95 percent price cut on the new rotavirus vaccine that can prevent diarrheal deaths.

As with most gifts and concessions, the process is ultimately a non-sustainable one, as the recipient community may still be unable to provide for itself. So who then, besides the drug companies, can a developing country turn to when a vaccine is desperately needed there?

Enter the World Health Organization (WHO) Technology Transfer Initiative (TTI), whose mandate is to promote increased access to health products through the transfer of technology and local production.

Dr. Martin Friede, Program Leader for the Technology Transfer Initiative (TTI), was in Singapore recently as part of a fact-finding delegation to learn more about Singapore’s bio-manufacturing model and to find common areas for collaboration.

Friede, who joined the WHO in 2003, received a PhD in biochemistry from the University of Cape Town, South Africa, and is the expert on all things vaccine. Prior to the WHO, he was a Vice President of Development at California-based vaccine biotech, Apovia Inc, and senior scientist at GlaxoSmithKline, where he led a team on vaccine formulation research.

Technology transfer = When + Which + Where + How

Friede describes technology transfer as a four-part series: the team first identifies whether a certain type of technology would improve health (when), before identifying the product (which), and then the recipient and donor (where). Then comes the hardest part: how best to conduct the technology transfer from a technology donor to its destination (how).

“We identified that frequently the best way is to find a non-profit somewhere, undertake a certain amount of development, and then from there give it to multiple centers. This technology transfer hub is wherever possible our preferred model,” he explained.

When a disease burden is identified – and this may vary widely from cardiovascular disease to hearing problems, the team then looks for an effective treatment to the disease. Next, the team looks for barriers to access such as cost, intellectual property situation, and feasibility. And in most cases, the barrier to access is a policy barrier, Friede says.

“Quite often, the absence of access is policy. The local government has not adopted a policy to using that intervention, either because they are not aware of it, or they have other priorities, or it is just not on their radar screen. And if policy is the barrier then we do not try to do technology transfer, we try to get other teams to assist the government to develop a policy,” he says.

If the technology is locked up as intellectual property (IP), Friede’s team will look out for when the patents expire, or countries where the product has not been patented in, or negotiate with the patent owners.

In other instances, feasibility may instead be the issue. A device may work very well in a hospital in Singapore, he explains, but not in a hospital in Sudan, because the electricity is failing, or the machines just aren’t maintained properly.

For example, in the event of an influenza pandemic, access to a vaccine may be hindered by absence of local capacity as well as limited global capacity. During a real emergency, governments from countries with local production may choose to store the vaccine as part of its national security policy, instead of sending it to other countries that are unable to manufacture their own.

“In the event of a pandemic, for a vaccine being produced in country A, you can be fairly sure that the government won’t allow it to go out of country A before everybody in country A has been vaccinated,” he says.

One solution for country B, C, and D, Friede says, is to produce their own vaccine, and to draw up a plan to scale up production during a pandemic.

But help does not come knocking to just any developing country. According to Friede, because the WHO is an international inter-governmental organization, member states must first request for help from the WHO team. The team then considers possible actions, inspecting the IP situation to find a licensing structure for that country, and ensuring that the project makes sense from both a health and economic perspective.

Even then, having the legal freedom to make the product isn’t enough, Friede says. Equally critical is the technological know-how and infrastructure to manufacture the product.

“If the manufacturer does not know how to make it, we need to find somewhere or someone to teach the manufacturer how to make it. Ideally we want to go to a country that already has a factory, that has most of the equipment already in place, so that the additional costs are already minimal,” he says.

Technology transfer is a game of push and pull, he explains. To entice local manufacturers to make the drug, the team tries to reduce the upfront costs and financial risks that these companies would have to undertake – this is achieved by various mechanisms such as providing seed funding, providing the know-how, training etc. Pull mechanisms include providing data on the disease burden and markets, but for some products such as vaccines may also include promoting the establishment of market commitments.

After sorting out the IP and manufacturing channels, the team then puts into place a value proposition.

“Because if you cannot, and if you don’t have a business plan, you don’t have a business,” says Friede a matter-of-factly, “and we cannot be promoting these ‘sinks’ where money just keeps getting sunk into them.”

But not all vaccines and health products need to be profitable, with the pandemic influenza vaccine a good example of an exception to the rule.

“In the case of pandemic influenza, this is a national security resource, so some countries have opted to view this as an exception that they will maintain that capacity in case there is a pandemic. That is a national prerogative to decide we are going to take that risk and make that investment,” he says.

Planting hubs around the world

Friede introduces the concept of a Center of Excellence, or ‘hub.’ Traditionally, technology transfer is a bilateral agreement between a MNC and a manufacturer, or between a university and a manufacturer, he says.

“This has been the common case for most technologies in developing countries but it is not very resource effective. Because the know-how goes to a single site,” he explains.

Instead, the team has established technology hubs that teach multiple manufacturers how to make the product, such as the influenza vaccine. And not only do multiple manufacturers acquire the technology, national regulators are also invited to visit the hubs to learn about the technology.

“There is very little point teaching a manufacturer how to make a product, if a national regulator does not know how to regulate this. This is in harmony, it goes hand in hand,” he says.

In this model, as long a manufacturer is able to build his factory appropriately, meet national regulatory requirements, and present a coherent business plan, he will likely make a product that results in improved health, Friede says.

The first such hub, he says, was the Netherlands Vaccine Institute (NVI), now called National Institute of Public Health and Environment (RIVM), where manufacturers from countries such as Mexico, Kazakhstan, India, Thailand, Vietnam, and Indonesia learnt how to develop the influenza vaccine “from A-to-Z.”

Everyone from the technicians, managers, directors, to national regulatory agencies could be trained how to make the product under Good Manufacturing Practices (cGMP) and also how to test and approve the products, he said.

Indeed, the process may expedite technology transfer and localize the know-how, but who pays for all of this?

Friede explains that in the case of the influenza hub, they issued a call for proposals from developing country vaccine manufacturers, who also needed to provide a letter from their government requesting for WHO assistance for that manufacturer.

Selected manufacturers then receive seed grants which vary from one country to another, leveraging on local public or private buy-in which is usually 17-20 times of the original funding. In one instance, the Indonesian government contributed 50 times of WHO seed funding.

“So some countries we were able to leverage; we provided the seed grants, and the local institutions behind contributed much more,” he says.

One success story is India, he says. According to Friede, the manufacturers they worked with had no experience in influenza vaccine development at the start of the project. Just two years later, the Serum Institute of India (SII) received approval for a locally made influenza pandemic vaccine.

“They are really an example of how a well trained workforce, commitment by the industry, plus some assistance from WHO enabled them to make a very good vaccine very quickly. We provided them a seed strain and negotiated a royalty free license for public sector sales to the technology,” he said.

Friede relates the story of his team’s work in Vietnam, which lacked a chicken farm and thus the supply of chicken eggs for viral production. In that particular case, the WHO contribution was straightforward: they simply financed the construction of a chicken farm as well as a water-treatment facility.

In another story, Indonesian adjuvant manufacturers learnt how to produce an oil-in-water emulsion adjuvant from the adjuvant technology transfer hub at the University of Lausanne in Switzerland. They are now performing clinical trials for the locally produced vaccine, he says.

Affordable rabies treatments

Another pet project of the team is the rabies monoclonal antibody technology transfer hub in Geneva, Switzerland.

“Rabies is a big problem in Asia. If you have been bitten by a dog, you have to assume that the dog has got rabies. You will receive first of all a rabies vaccine. But also, if the bite is more than superficial, you should receive post-exposure prophylaxis (PEP),” Friede explains.

PEP treatment of rabies these days takes place in the form of an immunoglobulin which is very expensive, he says. In addition, the immunoglobulin may also be derived from horses, and may result in dramatic allergies.

“So what we have been developing is a cocktail of monoclonal antibodies which will be as effective as the rabies immunoglobulin. We have collected various hybridomas which would appear to be needed to create this cocktail from WHO collaborating centers and we have provided this to two companies in India, and now to a research center in South Africa,” Friede says.

The South African research center is producing the antibodies in tobacco leaves, he says. Called plantibodies, the team hopes that the plant-derived antibodies may be cheaper to produce than those from hybridoma cell lines.

“But no plantibody that we are aware of has been injected into people. Plantibodies have been tested in trials by oral delivery, but not by injection,” he notes.

Singapore: the first WHO technology transfer hub in Asia?

With all the technology hubs based in Europe – one in the Netherlands and two in Switzerland, is the WHO Technology Transfer Initiative team hoping to establish its first hub in Asia?

Friede tells us that he is here to learn more about the city-state, and to find ways for both parties to collaborate and potentially for Singapore to host a Center of Excellence on bio-therapeutics.

He recalls a meeting in December last year in Cape Town, South Africa, where policy makers realized that the absence of a skilled workforce in the developing world is the biggest barrier to the sustainable production of vaccines there.

He then compares Singapore to South Africa, a country close to his heart. Unlike South Africa, which has a very weak bio-manufacturing cluster despite its excellent education system, Singapore has somehow managed to establish one in the span of thirty years.

Thus, Friede is here to understand the governmental policies that have led to the sustainability of its bio-manufacturing industry.

“Singapore is a highly unique country which has a large bio-manufacturing workforce that appears to be created by design. Thirty years ago, Singapore did not have a bio-manufacturing workforce. And now you have one of the leading bio-manufacturing workforces on earth,” he said.

One can only hope that these meetings have been fruitful for both Singapore and WHO, and wish Friede and his WHO team all the best as they tirelessly crisscross the world, transferring critical technologies to the developing world.

Source: Asian Scientist Magazine